Produk

Kualitas luhur ditumbuk Héjo Silicon Carbide pikeun Polishing na grinding

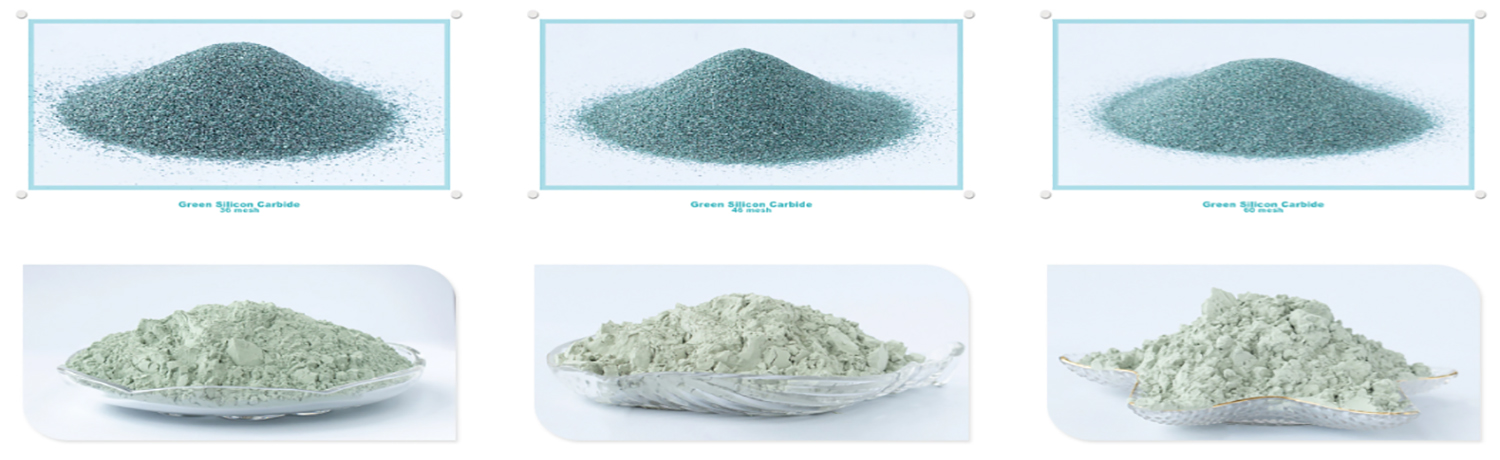

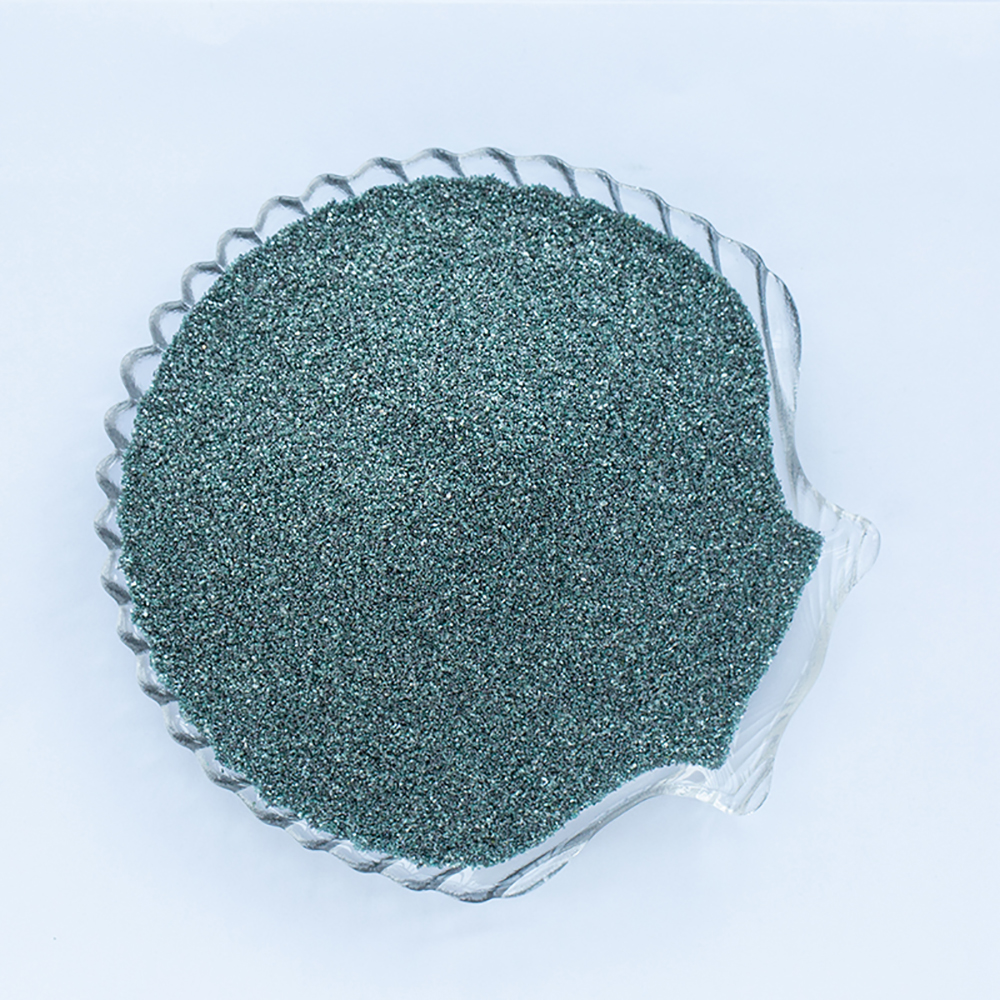

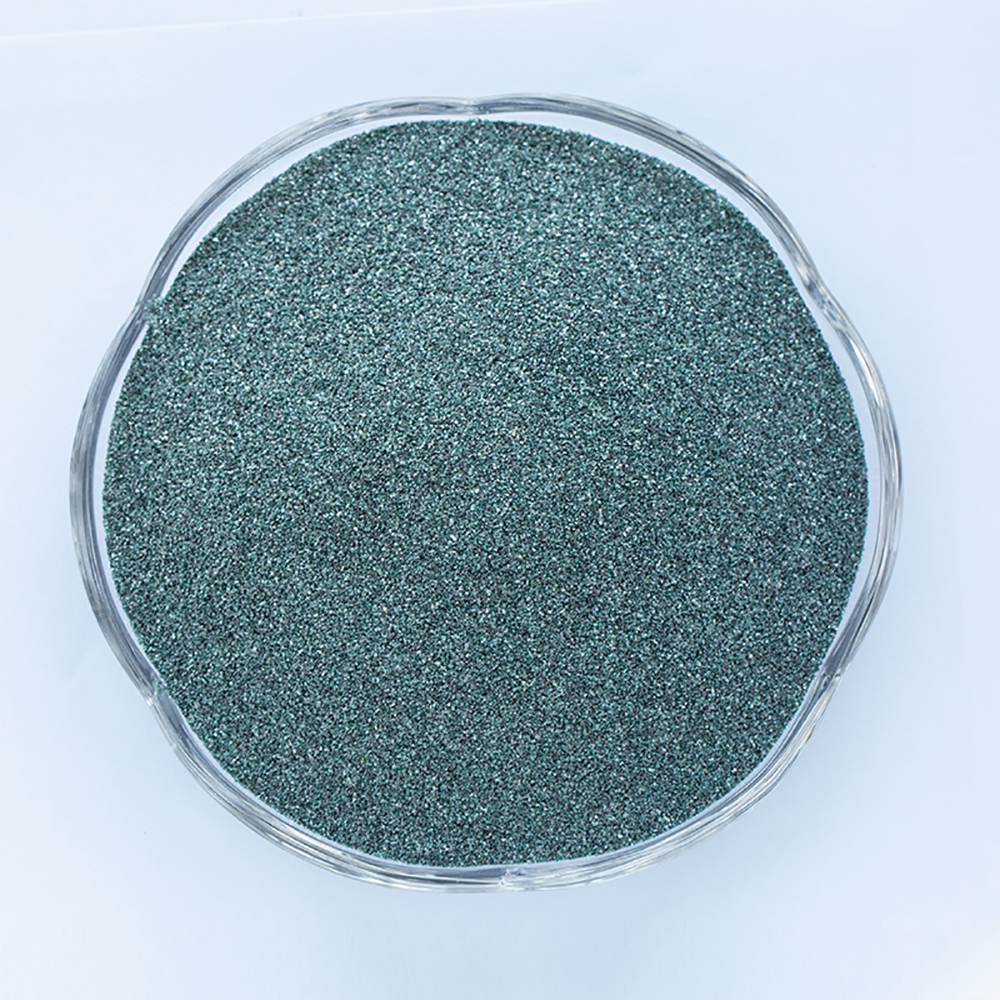

Héjo Silicon Carbide Pedaran

Héjo silikon carbide mangrupakeun bahan abrasive kualitas luhur dijieunna tina séréal silikon carbide na coke petroleum dina tungku lalawanan listrik dina suhu luhur.

Héjo Silicon Carbide Grit Ukuran

| Kelas sandblasting | 8#10#12#14#16#20#22#24#30#36#40#46#54#60#70#80#90#100#120#150#180#220# |

| Kelas ngagosok | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 |

| 240#280#320#360#400#500#600#700#800#1000#1200#1500#2000#2500#3000#4000#6000#8000# | |

| Catetan: urang ogé bisa ngaropéa nurutkeun sarat customer. | |

Héjo Silicon Carbide Kimia jeung Bulk Density

| Analisis Kimia | Kapadetan Bulk: LPD = Kapadetan Bungkus Leupas | ||||||

| Grit No. | Min. %SiC | Max. % C | Max. %SiO2 | Max. %Si | Max. % MI | Min. | Max. |

| 8# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.35 | 1.43 |

| 10# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.35 | 1.44 |

| 12# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.41 | 1.49 |

| 14# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.42 | 1.50 |

| 16# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.43 | 1.51 |

| 20# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.44 | 1.52 |

| 22# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.44 | 1.52 |

| 24# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.45 | 1.53 |

| 30# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.45 | 1.53 |

| 36# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.46 | 1.54 |

| 40# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.47 | 1.55 |

| 46# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.47 | 1.55 |

| 54# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.46 | 1.54 |

| 60# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.46 | 1.54 |

| 70# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.45 | 1.53 |

| 80# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.44 | 1.52 |

| 90# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.44 | 1.51 |

| 100# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.42 | 1.50 |

| 120# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.40 | 1.48 |

| 150# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.38 | 1.46 |

| 180# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.38 | 1.46 |

| 220# | 99.00 | 0.40 | 0.40 | 0.50 | 0,0200 | 1.36 | 1.44 |

1.Abrasive: Héjo silikon carbide ieu loba dipaké salaku bahan abrasive di sagala rupa industri, kaasup otomotif, aerospace, metalworking, sarta perhiasan.

2.Refractory: furnaces na kilns alatan konduktivitas termal tinggi sarta ékspansi termal low.

3.Electronics: LEDs, alat kakuatan, jeung alat gelombang mikro

énergi 4.Solar: panels surya.

5. Metalurgi

6.Ceramics: parabot motong, maké-tahan bagian, sarta komponén-temperature tinggi

Pananyaan anjeun

Mun anjeun mibanda patalékan. Mangga ngarasa Luncat ngahubungan kami.

formulir panalungtikan

Tulis pesen anjeun di dieu sareng kirimkeun ka kami