Produk

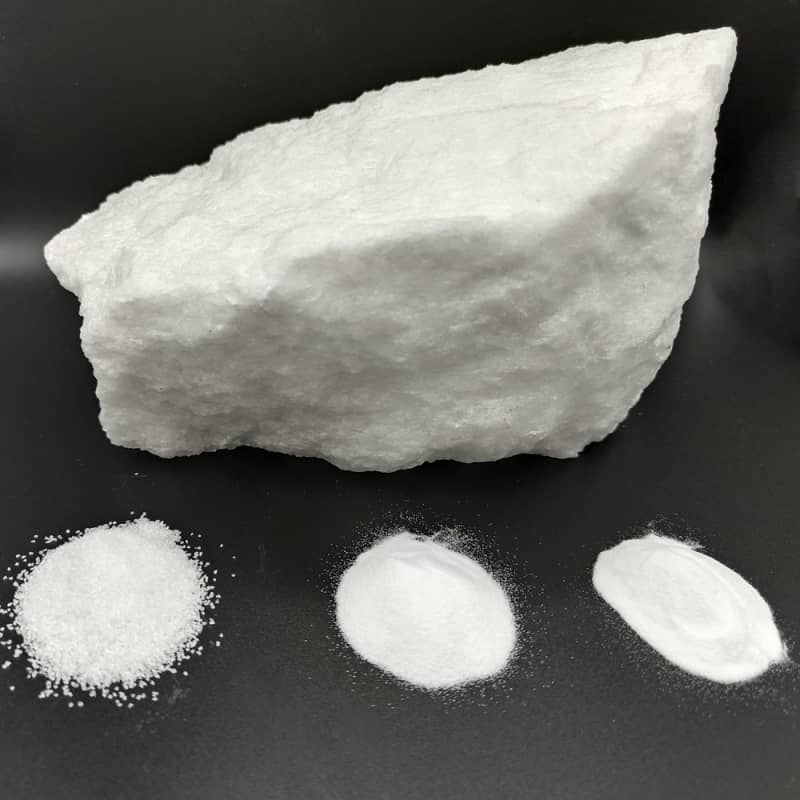

Bahan Abrasive Bodas ngahiji Alumina Grits

Alumina ngahiji bodas mangrupa bubuk alumina salaku bahan baku, rutin di luhur 2000 ℃ suhu luhur smelting tungku arc listrik, sanggeus smashing plastik, separation magnét kana beusi, layar dibagi kana rupa-rupa ukuran partikel, tékstur padet, karasa tinggi, formulir granular Angle karasa. leuwih luhur ti coklat ngahiji alumina rada, kateguhan rada handap, gaya motong kuat sarta stabilitas kimiawi téh alus, boga insulasi pohara alus.

Bodas ngahiji alumina dijieunna tina-purity tinggi low-natrium bubuk alumina ku lebur dina suhu luhur, cooling kristalisasi, lajeng crushing.The bodas ngahiji alumina grit sahandapeun ngadalikeun ketat pikeun ngajaga distribusi ukuran sisikian jeung penampilan konsisten.

Ilahar dipaké dina castables ladle, bahan runner beusi, bahan campuran gunning refractory jeung produk refractory monolithic séjén;

Pikeun bahan refractory ngawangun, utamana dipaké dina bahan baku kualitas luhur bata corundum, corundum mullite, pemurnian baja porous colokan bata, gun semprot integral, steelmaking jeung industri casting kontinyu.

Ogé bisa dipaké salaku bahan pikeun polishing, casting precision, nyemprot jeung palapis, keramik husus

Bodas, kristal α leuwih 99%, purity tinggi, karasa tinggi, sarta kateguhan tinggi, gaya motong kuat, stabilitas kimiawi kuat, sarta insulasi kuat.

| Mohs karasa | 9 |

| Kapadetan bulk | 1,75-1,95g / cm3 |

| Gravitasi husus | 3,95g/cm3 |

| Kapadetan volume | 3.6 |

| darajat lebur | 2250 ℃ |

| Gelar refractory | 2000 ℃ |

Dipaké pikeun refractory, castable

| Pasipatan | 0-1 1-3 3-5m/m | F100 F200 F325 | |||

| Nilai Jaminan | Nilai has | Nilai Jaminan | Nilai has | ||

| Komposisi kimiawi | Al2O3 | ≥99.1 | 99.5 | ≥98.5 | 99 |

| SiO2 | ≤0.4 | 0.06 | ≤0.30 | 0.08 | |

| Fe2O3 | ≤0.2 | 0.04 | ≤0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤0.40 | 0.35 | |

Dipaké pikeun abrasives, blasting, grinding

| Tipe Pasipatan | Biji-bijian | ||

| 8#10#12#14#16#20#22#24#30#36#40#46#54#60#70#80#90#100#120#150#180#220# | |||

| Nilai Jaminan | Nilai has | ||

| Komposisi kimiawi | Al2O3 | ≥99.1 | 99.5 |

| SiO2 | ≤0.2 | 0.04 | |

| Fe2O3 | ≤0.2 | 0.03 | |

| Na2O | ≤0.30 | 0.2 | |

Dipaké pikeun abrasives, lapping, Polishing

| Tipe Pasipatan | bubuk mikro | |||

| "W" | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 | |||

| "FEPA" | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| "JIS" | 240#280#320#360#400#500#600#700#800#1000#1200#1500#2000#2500#3000#4000#6000#1000#1000# | |||

| Nilai Jaminan | Nilai has | |||

| Komposisi kimiawi | Al2O3 | ≥99.1 | 99.3 | |

| SiO2 | ≤0.4 | 0.08 | ||

| Fe2O3 | ≤0.2 | 0.03 | ||

| Na2O | ≤0.4 | 0.25 | ||

1.There euweuh pangaruh ngeunaan warna bagian olahan.

2.It bisa dipaké dina prosés dimana résidu bubuk beusi mastikeun dilarang.

3.Shaping séréal pisan cocog pikeun sandblasting baseuh jeung operasi polishing.

1.Sandblasting, polishing na grinding logam jeung kaca.

2.Filling tina cet, ngagem-tahan palapis, keramik, sarta glaze.

3. Making of grinding kabayang, sandpaper jeung lawon Emery.

4.Production mémbran filter keramik, tabung keramik, pelat keramik.

5.For pamakéan lanté maké-tahan.

6.Sandblasting tina papan circuit.

7.Sandblasting kapal, mesin pesawat, jalur karéta jeung awak luar.

8.Various bodas datar séréal oksida aluminium bisa dihasilkeun nurutkeun tungtutan béda konsumén '.

Pananyaan anjeun

Mun anjeun mibanda patalékan. Mangga ngarasa Luncat ngahubungan kami.